Woven for the Future: Safeguarding Textile Knowledge and Accelerating Workforce Training with Mixed Reality

In the heart of Western North Carolina’s historic textile region, a groundbreaking collaboration is transforming how the next generation of workers is trained for the future of manufacturing. The U.S. National Science Foundation (NSF) funded 9 innovation engines across the US. One of these Engines focuses on textile innovation in the Southeast US and is led by The Industrial Commons based in Morganton, NC. The NSF The Textile Innovation Engine of North Carolinahas partnered with Western Piedmont Community College and industry leader Valdese Weavers to launch a groundbreaking mixed reality (MR) training module, one that’s redefining how the next generation of textile workers learn critical skills.

The Textile Innovation Engine and Western Piedmont Community College focused on their partnership with Valdese Weavers as they are the 5th largest employer and largest manufacturing operation in the county. At the center of this innovative training is a fundamental, hands-on task: how to fix a warp stop loom and tie a weaver’s knot. Traditionally, it takes up to a year of on-the-job learning to master skills as a weaver, but using Apple’s Vision Pro headset and the immersive power of mixed reality tools blending the physical and digital worlds, the training offers the possibility of mastering the same skills in just 2-3 months.

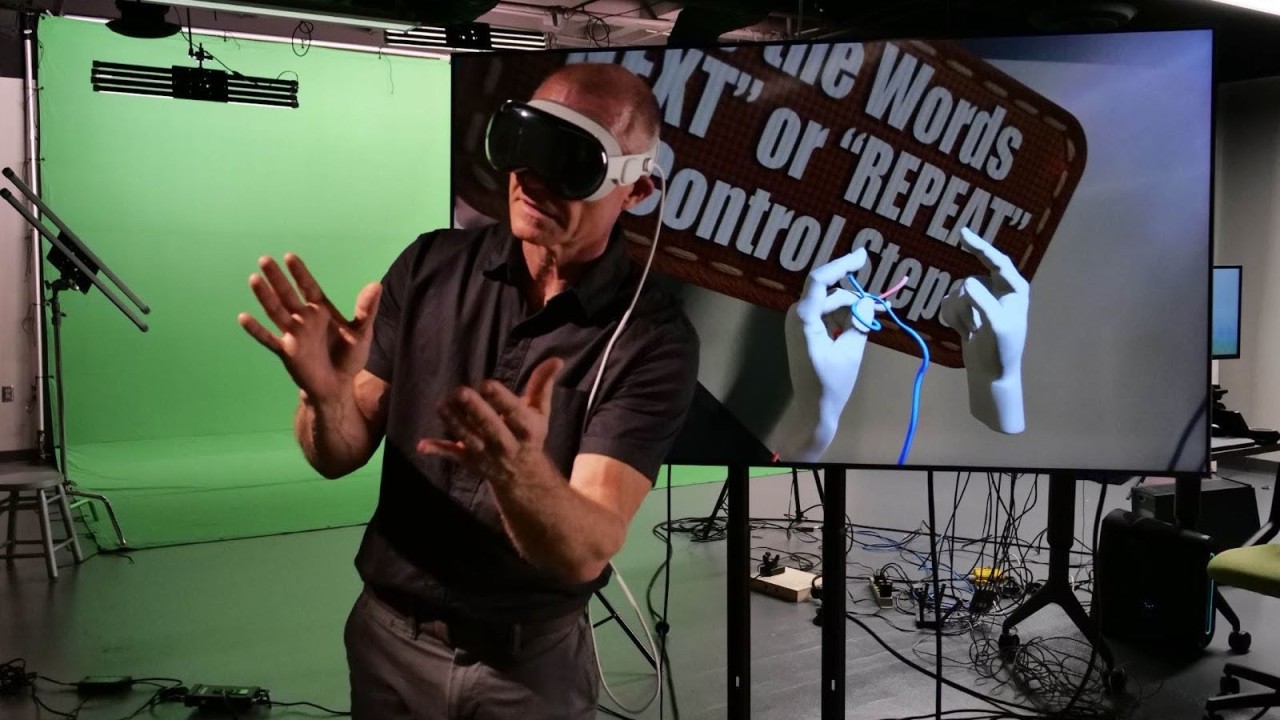

In this immersive learning environment, trainees engage with floating, interactive modules that guide them step-by-step through complex textile processes like tying a weaver’s knot. The platform supports all learning styles—auditory, visual, and kinesthetic—creating an experience that feels like having a personal trainer alongside you. While the current training takes place in a controlled setting, the technology’s pass-through visual capabilities, which allow users to see their physical surroundings while interacting with digital content, open the door to one day using it safely on the factory floor. With retina-tracking calibration and the potential for future multilingual translation, the platform is designed for both precision and accessibility, offering a powerful tool for a more inclusive and adaptive workforce.

Launched in February, the project began when WPCC, one of the founding partners of the NSF-funded Textile Innovation Engine, received support to explore new approaches to workforce development using mixed reality. Together with Valdese Weavers, the team identified a specific, high-impact skill to focus on and began prototyping the MR training experience. Students in WPCC’s media creation programs were integrated into the development process from the start, working alongside game designers and engineers to bring the simulation to life.

This innovation arrives at a critical time, as the aging textile workforce faces an urgent need to pass on hard-earned technical knowledge to a new generation. Without intervention, essential skills like loom operation and knot-tying risk being lost within the next decade. The mixed reality training platform offers a powerful solution to safeguard these core competencies and respond to a rapidly shifting industry. Beyond its immediate application, the MR experience has the potential to expand into quality control, troubleshooting, and other vital operations. It also opens new avenues for curriculum development, with WPCC faculty planning to integrate simulation tools into media courses, further strengthening the region’s growing textile innovation ecosystem.

This collaboration is redefining what’s possible for workforce development in legacy industries. As Wasef Awad, Plant Manager at Valdese Weavers, shared: “This partnership is a powerful example of how education, industry, and technology can come together to shape the future of American manufacturing. It has helped us unlock new possibilities for innovation and workforce development.” Rooted in tradition and driven by innovation, this work signals a bold future for textiles in North Carolina and beyond.

Quelle:

Foto: Jonathan Crumpler, Assistant Dean of Business and Technologies tests the mixed reality training prototype designed to teach the weaver’s knot.

https://www.linkedin.com/pulse/woven-future-accelerating-workforce-training-mixed-fzpqe